Jigs and fixtures have long been a part of manufacturing. But conventional jigs and fixtures also have shortcomings beyond their benefits. This is especially true when small production runs are not repeated regularly.

Jigs and fixtures are usually designed for specific tasks or products. As a result, they may lack versatility and flexibility. If there are frequent changes in the production process or product design, modifying or creating new jigs and fixtures may be necessary, adding to the overall costs.

When a company adds modular fixturing to its capabilities, even job-shop-type production can be more successful.

What is Modular Fixturing?

Modular fixturing is a workholding system that uses standardized components for building specialized workholders. A workholding system is a collection of tools, devices, or mechanisms to securely secure and hold a workpiece during various machining, manufacturing, or assembly processes. The goal is to provide stability and ensure accurate positioning of the workpiece.

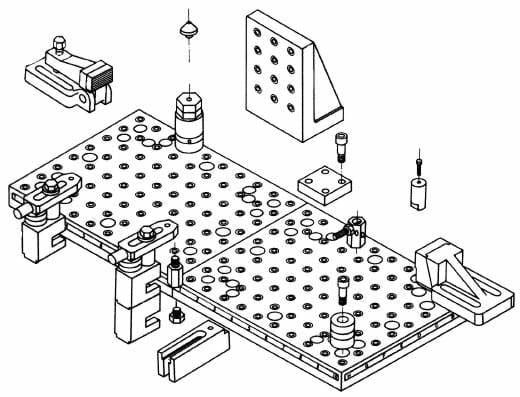

Figure 6-1 shows that a modular workholder is assembled from various standard off-the-shelf tooling plates, fixture plates, supports, locating elements, clamps, and similar components.

The components are assembled with socket-head cap screws and locating screws. A modular-fixturing system may have hundreds of different elements. The components can be assembled in different combinations to build an unlimited variety of workholders.

Figure 6-1. Modular workholders can be assembled entirely from standard off-the-shelf components.

Figure 6-1. Modular workholders can be assembled entirely from standard off-the-shelf components.

The assembly process is quite simple. Components are designed to be used together, each with an identical hole pattern. To build a workholder, the components are simply positioned as required and attached with locating or fastening screws.

The simplicity reduces training time and permits technicians to build workholders almost immediately. Regardless of the manufacturing operations, modular systems can provide workholders for almost any workpiece.

Do You Need to Implement Modular Fixturing?

Modular fixturing is not intended for every workholding operation. Still, when appropriate, it increases production and reduces fixturing costs. Modular fixturing is not a replacement for permanent fixturing. It is an upgrade from “no fixturing” and is just a step below permanent fixturing.

The Hierarchy of Workholding Fixture Options

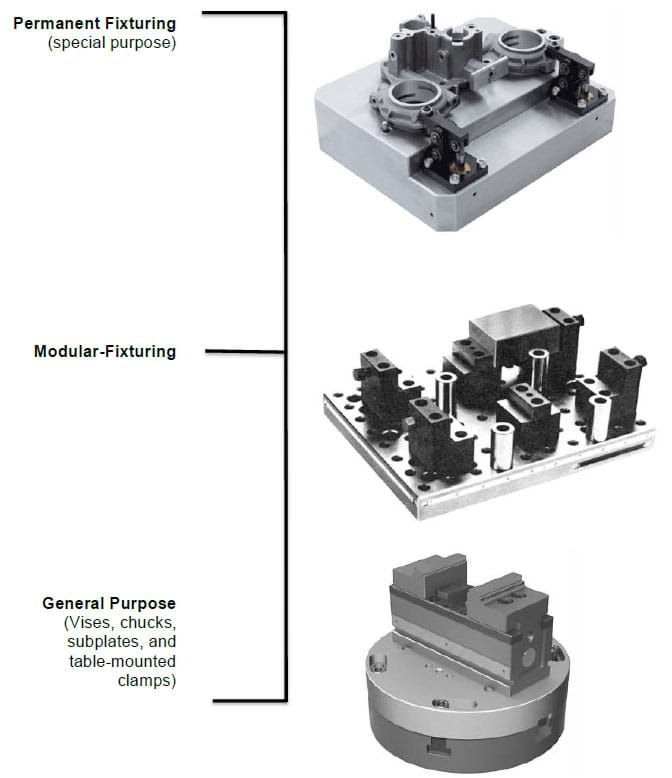

To understand how modular fixtures relate to workholding in general, it’s necessary to be aware of the various forms of workholders. Workholder forms can be grouped into three general categories, Figure 6-2.

The least-complicated tools are the general-purpose workholders. The most complex and most-detailed workholders are the special-purpose or permanent fixtures. Between the two are modular fixtures. Modular fixturing bridges the gap between the general-purpose and special-purpose workholders.

Although the three forms of fixturing may seem completely different, each is a further development or refinement in the workholding process.

Figure 6-2. The hierarchy of workholding options. Modular fixturing fills the significant gap between general purpose and permanent workholders.

Figure 6-2. The hierarchy of workholding options. Modular fixturing fills the significant gap between general purpose and permanent workholders.

General-Purpose Workholders

These are the simplest form of fixturing devices. This category includes various standard clamps, vises, chucks, and similar standard off-the-shelf components. General-purpose components are reusable and usually the least expensive. Although these components represent a smaller initial investment, they are often inadequate or unsatisfactory for complex parts or high-volume production.

Permanent Workholders

These are designed and constructed for a single workpiece or family of parts. Even though these workholders are typically the most efficient, they are also the most expensive. Permanent workholders are built with various standard and custom-made parts to meet specific requirements. These fixtures are the best choice for high-volume or repeated production runs.

Modular Workholders

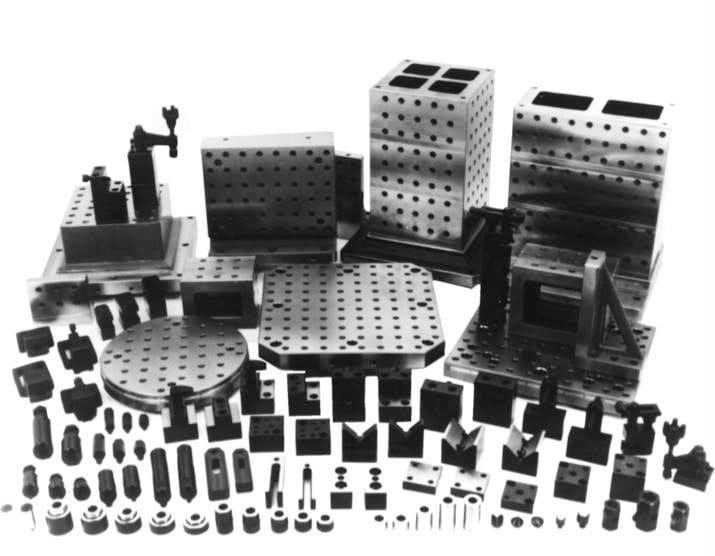

In the most basic sense, modular workholders can be described as special-purpose workholders assembled from general-purpose components. Figure 6-3 shows a typical system of modular-fixturing components.

Modular fixturing, rather than a departure from conventional fixturing methods, combines the best attributes of both unique- and general-purpose workholding methods. Modular fixtures are built with the accuracy and detail of special-purpose workholders but with reusable and universal components. These fixtures are similar in cost to general-purpose workholders.

Figure 6-3. Typical components of a modular-workholding system.

Figure 6-3. Typical components of a modular-workholding system.

Applications for Modular Fixturing

Modular workholders are best suited for one-time jobs, infrequent production runs, prototype parts, replacement parts, trial fixturing, and temporary tooling.

One-Time Jobs

One-time jobs are more common in job shops and are ideal for modular fixturing. A workholder can be economically built with modular fixturing, even for a one-part run.

In most job shops, each machine tool does various tasks in a single day. With modular fixturing, jobs can be performed with specialized workholders at a cost very competitive with crude machine-table setups. Here, modular fixtures increase quality and accuracy while maintaining competitive costs.

Infrequent Production Runs

Jobs that do not repeat regularly are well suited for modular fixturing. Today, shorter lead times are becoming more common. Modular fixturing allows for rapid setup of short-notice production runs. Once again, modular workholders offer many benefits of special-purpose tooling at a fraction of the cost.

Prototype Parts

Prototype or experimental parts frequently require special workholders. Since prototype workpieces are often changed or redesigned, the cost of building jigs or fixtures for each new variation can be high.

Modular fixturing is the best alternative. With modular workholders, each workpiece variation can be quickly fixtured with little or no downtime.

Replacement Parts That Are Made to Order

Replacement parts are an expensive problem for many organizations. In the past, these parts were made in large lots and placed in storage. Some parts were quickly sold, while others were never ordered.

Modular fixturing eliminates the need for an inventory of slow-moving replacement parts. Modular fixturing permits a company to respond to orders as they are received. Instead of shipping parts from an inventory, parts can be made as needed.

Trial Fixturing Techniques

Trial fixturing is common throughout manufacturing organizations. Before any product goes into production, workholders must be designed, built, and tested. Assembling a modular workholder for a workpiece allows the tool designer to test new tool designs and find problem areas. Modular workholders allow designers to fine-tune tooling ideas before a final production workholder is built.

While Permanent Fixtures Are Built or Repaired

No matter how well a permanent jig or fixture is built, most require repair or maintenance. A modular workholder can easily be assembled and placed into production while the permanent workholder is repaired. Modular fixtures also buy time for the initial building of permanent fixtures without delaying production.

Poor Applications for Modular Fixturing

Just as conventional machine tools are better suited for some tasks than expensive CNC machines, the selection and application of workholders is determined by the work that needs to be performed.

Modular workholders are not intended for every job. Two limiting factors with modular workholders are the frequency of production runs and the size of the workholder.

Jobs That Will Repeat Many Times

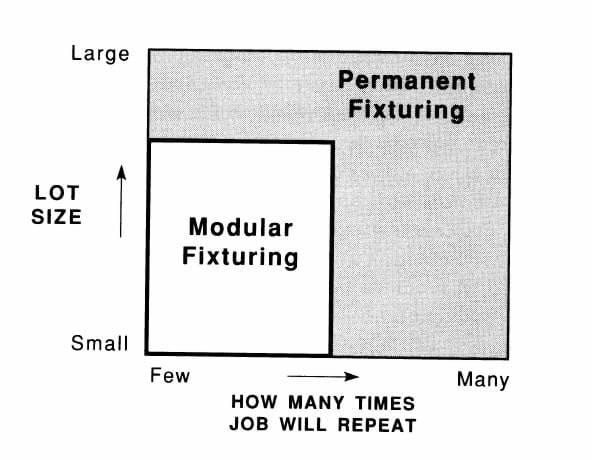

Recurring production runs are those that repeat regularly. The choice of fixturing method depends more on the frequency of production runs than on the number of parts per run.

As shown in Figure 6-4, choosing between modular and permanent fixturing for a particular job depends on how often the job will run, not just on lot size.

Modular Workholders are Usually Disassembled After Each Job

Each time a job is run, the modular fixture requires reassembly. Permanent workholders are normally built for a complete production run. If a job repeats on a regular basis, a permanent fixture is the better choice.

Modular fixtures could remain assembled between production runs, thus becoming a permanent workholder, but this negates the economy of reusing modular components.

Where Fixture Compactness Is Important

Another factor to consider in selecting a workholder is the size of the completed fixture. As a rule, modular workholders tend to be larger than their special-purpose counterparts. Permanent workholders are usually built from a custom fixture or custom-made elements and baseplates that permit a smaller, more compact workholder.

Modular components are intended for various applications and, though more universal, are larger than comparable custom-made components. So, when space is limited, such as with multiple-part setups, modular workholders may be too large.

Figure 6-4.Choosing between modular and permanent fixturing depends mainly on how often a job will run, not just on lot size.

Figure 6-4.Choosing between modular and permanent fixturing depends mainly on how often a job will run, not just on lot size.

Explore Modular Fixturing Solutions at Carr Lane Mfg.

Carr Lane Mfg. offers two modular fixturing system sizes for various applications. Explore products and corresponding parts in our online catalog.

Browse products