3-Axis Milling

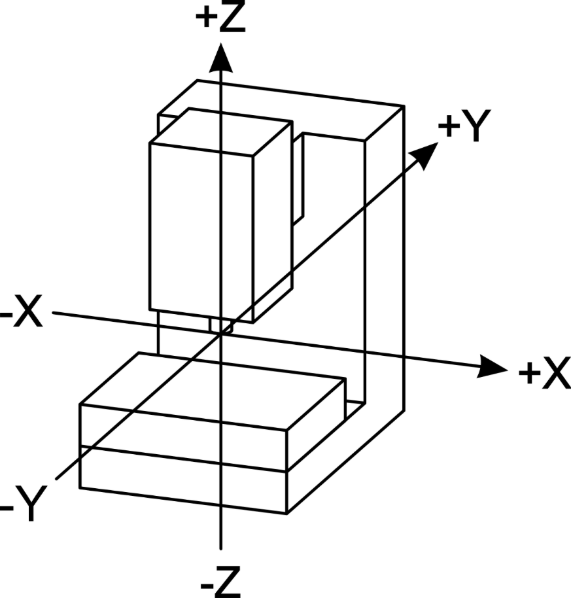

3-axis milling is the foundational CNC machining process used for most milled components. The cutting tool moves along three linear axes, X, Y, and Z, while the workpiece remains fixed in a single orientation. Nearly all fundamental milling operations take place within this framework, including facing, pocketing, contouring, drilling, and tapping.

3-axis milling is ideal for parts that can be reached from one side or from multiple sides through manual refixturing. Accuracy depends on proper fixturing, repeatable datums, and rigid clamping. Because the part cannot be tilted or rotated in orientation to the cutting tool, access to features is limited by tool length and tool approach angle. Deep features, undercuts, and complex geometries often require multiple setups or cannot be reached at all.

3-axis machining remains the core of most machining because of its simplicity, reliability, and compatibility with a wide range of tooling and workholding systems.

Multi-Axis Milling

Multi-axis milling expands the capabilities of standard 3-axis machining by introducing one or two additional axes. These rotary axes allow the part or the tool to be oriented at different angles without manual refixturing. Multi-axis configurations include 3+1, 3+2, and full simultaneous 5-axis motion.

In 3+1 and 3+2 machining, the rotary axes position the part or tool to the required angle, then hold that orientation while cutting takes place using standard 3-axis toolpaths. This allows efficient access to multiple faces of a part in a single setup and supports the machining of angled features, compound holes, and surfaces that cannot be reached from orthogonal directions.

Simultaneous 5-axis milling uses continuous, coordinated movement of all linear and rotary axes. This enables smooth tool orientation control, improved surface finish, shorter cutters, and optimal cutting angles for complex 3D shapes. Simultaneous 5-axis requires a rigid machine structure, high-performance controls, and precise rotary assemblies.

Depending on the configuration, rotary motion can be introduced through rotary indexers, tilting tables, trunnion tables, or integrated 5-axis systems. Trunnion tables may or may not allow for simultaneous 5-axis machining, depending on the machine tool and control configuration. The specific method of adding rotary motion will be discussed in later sections.