What is a 4th Axis?

A 4th axis is a rotary axis added to a standard three-axis machining center to allow controlled rotation of a workpiece around a horizontal or vertical centerline. In a typical vertical machining center, the 4th axis is mounted on the machine table and provides rotation around the X axis. This converts a standard 3-axis machine into a system capable of machining multiple sides of a part without manual refixturing.

A 4th axis includes a rotary drive system, a precision bearing assembly, a workholding interface, and a braking or locking mechanism. The drive and feedback systems control angular position, while the brake increases holding torque during cutting. By rotating the part into different orientations, a 4th axis improves access to features, reduces setups, and supports both positional and semi-complex angular machining.

Most 4th axes can operate in either positional mode or continuous mode. In positional mode, sometimes called indexing, the axis rotates to a programmed angle and locks. In continuous mode, the rotary axis turns while cutting takes place. Continuous rotation is typically used for cylindrical profiling, gear work, and special milling operations, but full simultaneous multi-axis motion requires a second rotary axis.

A 4th axis expands the capability of a machining center by shortening tool reach, improving access to multiple sides of a part, and allowing consistent feature-to-feature accuracy across several faces. (Need illustrative image)

Common Types of 4th Axes

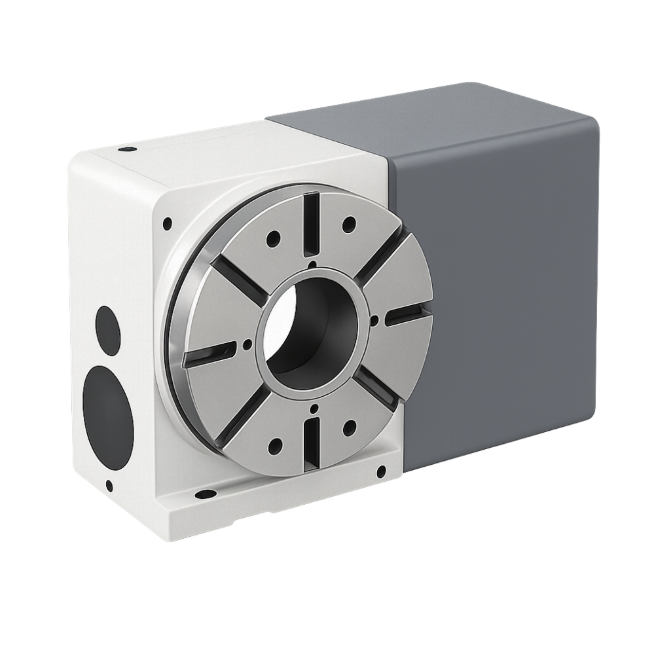

Single Rotary Indexer

A single rotary indexer provides controlled rotation around one axis. It is used to position the workpiece at specific angles, then hold that angle during machining. The workpiece does not tilt, only rotates.

These systems often rely on a worm gear or similar drive, along with a mechanical or pneumatic brake.

Rotary Table

A rotary table functions similarly to an indexer but is typically designed for heavier parts, and higher machining forces. Many rotary tables include large diameter bearings, higher gear reduction, and stronger braking systems.

Rotary tables can be manual, CNC driven, or high-speed depending on the application.

Tilting Rotary Table

A tilting rotary table introduces a second rotary motion built into the assembly. The base provides rotation around the X axis, while the upper cradle tilts around a perpendicular axis. Although still considered a 4th axis device when used alone, this style is often used as one half of a 5-axis configuration.

Tilting tables reduce available workspace and usually include outboard supports for longer tooling setups or larger fixtures.

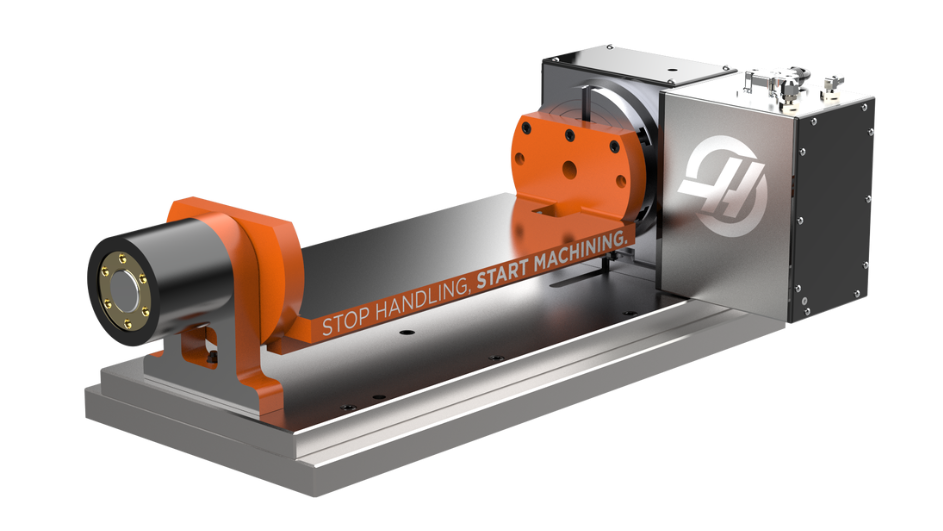

Trunnion Style Rotary Axis

A trunnion assembly mounts a fixture platform or subplate to a rotary axis. The rotary axis is horizontal, and the trunnion plate rotates around that axis. Trunnions support long fixtures, multi-part setups, and large work envelopes.

Trunnions often use outboard bearings or supports to prevent sag or deflection under load.