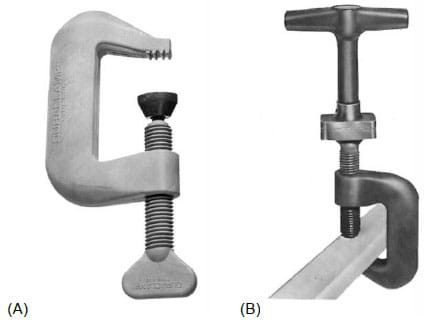

C Clamps are widely used in most types of manufacturing. They are portable clamping devices, but are sometimes used on fixtures, especially in finishing operations. They incorporate a screw clamp into a C-shaped frame. The Duraclamp C Clamp, shown in Figure 8-68, is a fiberglass-reinforced thermoplastic clamp designed for the corrosive conditions often encountered in finishing operations. These lightweight C clamps are made in four sizes and have large thumb screws for easier tightening. A torque wrench and socket combination (b) is also available for precise clamping force. The wrenches are preset to 50 inch-pounds of torque, suitable for most clamping operations.

Figure 8-68. Duraclamp C Clamps and accessories. These high-strength plastic C clamps are used in

corrosive environments.

Figure 8-68. Duraclamp C Clamps and accessories. These high-strength plastic C clamps are used in

corrosive environments.

SWING C CLAMPS

These C clamps have a hinged pad for fastening permanently to a fixture, allowing them to swing clear for workpiece loading, Figure 8-69. The hinged mounting pad bolts to the fixture with two socket-head cap screws. Four-prong knob provides a firm grip for applications requiring quick tightening and high torque. Clamping screw is cast securely in the knob and has a removable swivel foot.

Figure 8-69. Swing C Clamps can be permanently fastened to a fixture

Figure 8-69. Swing C Clamps can be permanently fastened to a fixture