What is an ID or Bore Clamp?

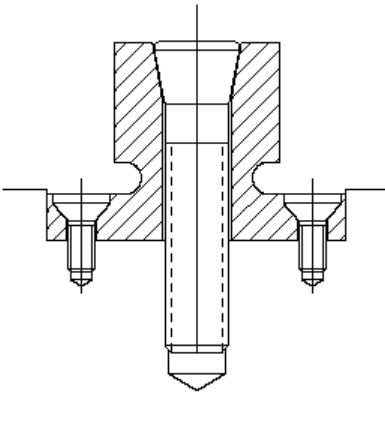

ID, or Bore clamps, expand within a hole or bore to self-center and clamp on the inside diameter of a workpiece, leaving the outside clear for machining. ID clamps allow close mounting for multi-part machining on vertical and horizontal machining centers. ID clamps are designed to have their outside diameter finish machined by the customer to suit the bore size, because maximum diameter expansion is limited (.005 to .025", depending on the size) A recessed dowel pin may be installed into the flange for additional rigidity if required.

(image from product catalog of application)

How does a Manual ID or Bore Clamp Work?

Tightening the tapered center screw of ID clamps with a hex wrench pushes the clamping segments outward, and slightly downward, to exert force on the workpiece's internal bore.

(Image from product catalog)

Machining an ID Clamp to Size

Expand clamp approximately .002 to .003 over the relaxed diameter while machining the clamp outside diameter to fit to the work piece bore either on lathe or mill. If using a chuck, use the nut provided to expand the clamp. This nut is used only while machining the clamp. If using a mill, machine a pocket in the fixture for the close tolerance flange outside diameter dimension and drill and tap mounting holes per Mounting Screw dimensions. Drill and tap a hole from the “S” dimension column in the center of the pocket for the tapered center bold. Expand the clamp and mill to size.