5 Axis Workholding Solutions For All Rotary Tables

The CL5® 5-axis workholding system offers a wide range of solutions for any sized rotary table.

There are three primary methods of applying these workholding systems, each designed for a specific application.

The CL5® 5-axis workholding system consists of a selection of 5th Axis vises, quick-change risers, precision centering vise products, subplates and other accessories.

Learn more about each of these products, manufactured by ROEMHELD North America and how they can be applied to your Rotary Table.

If you have a specific question, contact our engineering department by calling 314.647.6200 or emailing us at [email protected].

METHOD 1: Fixture Plate Mounted on Rotary Table

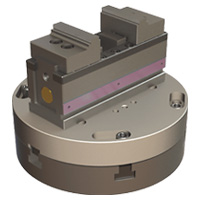

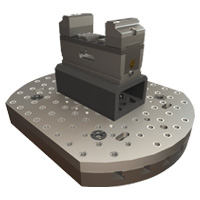

Vise-Adaptor Fixture Plate with 5-Axis Vise

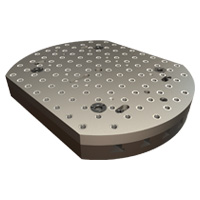

Modular Fixture Plate

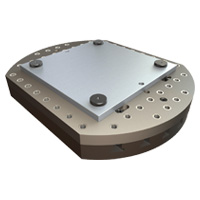

Modular Fixture Plate with Riser Block

Blank Fixture Plate

Method 1 is ideal for small rotary tables up to 210mm diameter but can also be used for larger tables up to 400mm diameter. In this installation method, fixture plates are accurately located and fastened directly on the rotary table. This simple, economical method allows using 5-Axis Machining Vises, modular fixturing, or dedicated permanent fixturing.

Carr Lock® Fixture Plates are precision-machined MIC-6 cast aluminum plates available in a wide range of standard sizes to use as a base for building quick-change fixtures. These fixture plates are quickly located and mounted on a subplate using Carr Lock® Clamps.

METHOD 2: METEC 5-axis Quick Change Risers Mounted on Rotary Table

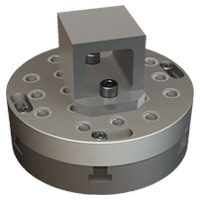

P8-Metec Riser

PC 80 F Riser

Method 2 utilizes our ROEMHELD METEC 5-axis Quick-Change Risers to achieve full quick-change fixturing benefits on rotary tables and are used with PC80 and MCP60 vises. A METEC Quick-Change Riser provides additional height for spindle clearance and can be quickly and accurately mounted directly on the rotary table at its center.

METEC Risers, from ROEMHELD North America, are specially designed to elevate the workpiece from the table to provide spindle clearance. To reduce weight, while maintaining strength, it is precision machined from 6061 Aluminum. It mounts easily to most machines and may be mounted in several positions utilizing either a ½" or M12 Socket head cap screws.

This riser can be accurately located to machining centers of a workholding fixture or rotary tables using a Center Locating Key (CLM-25-CLK-50).

METHOD 3: Subplate Mounted on Rotary Table

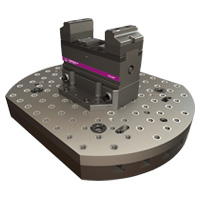

Subplate with Quintus Riser and 5-Axis Vise

Subplate with Riser Block

Subplate with Carr Lock Fixture Plate

Subplate used as Modular Fixture Plate

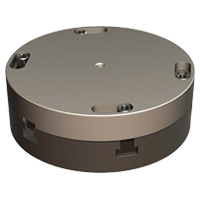

Method 3 is appropriate for medium and large machine tables, achieving further quick-change benefits for the entire riser assembly. Using this method, the Quintus riser is mounted on a subplate to allow quick exchange of the riser with other fixturing.

Carr Lock® Subplates serve as the foundation of an efficient quick-change fixturing system. Subplates should generally be large enough to cover most of the machine table, for maximum fixture flexibility, but should never extend beyond the machine table.

For maximum quick-change benefits, subplates are usually left permanently on the machine table while only the mounted fixtures or vises are exchanged.

For more information and to purchase products, visit the CL5® 5-Axis Workholding product page for top tooling components.