Precision vises are a group of general-purpose power Workholders designed to hold many different workpieces. These universal fixtures come in three basic forms: 5-axis vises, machine vises and self-centering vises.

Standard Machine Vise Information

Standard Machine Vises have one Fixed Jaw and one Moving Jaw. The moving jaw advances towards the fixed jaw by rotating a screw, for a manual vise, or through the use of an Air or of Hydraulic Piston. Available in a large variety of sizes, lengths, clamping forces, and actuation methods vises are a common workholder. Vises are frequently used in both Vertical and Horizontal Machining centers.

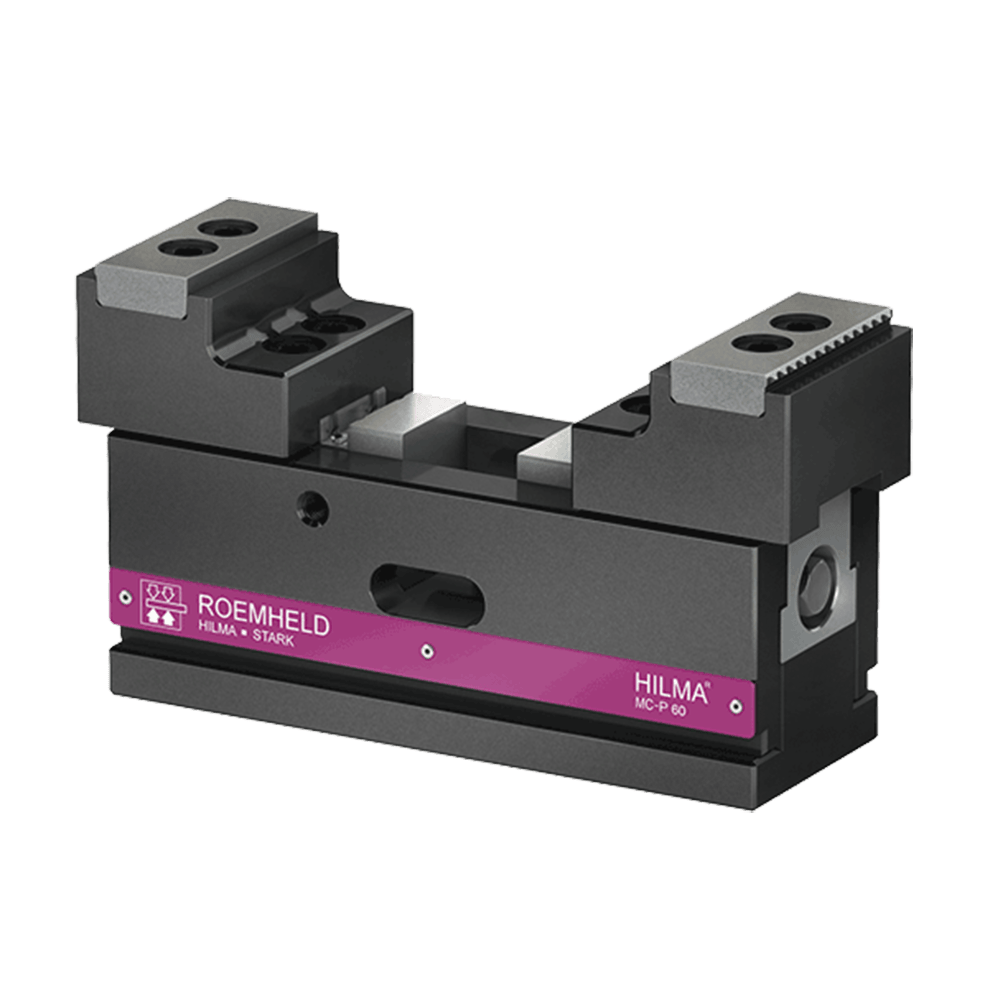

5-Axis Vise Information

5-Axis vises, unlike Standard Machine Vises, commonly use a Concentric design where each jaw moves towards the center of the vise. They also are frequently square in design which provides a sufficient jaw width while remaining compact in their length allowing them to better fit onto Rotary tables, trunnion tables, and the like. Unlike Standard Machine vises output force from 5-axis vises usually is lower than Standard vises for a variety of reasons which include differences in materials used to make the vise. Commonly Aluminum is used for the base of the vise which can flex and bend during clamping resulting in a reduction of the force applied to the workpiece. Watch our Jaw Lift and Downforce video.

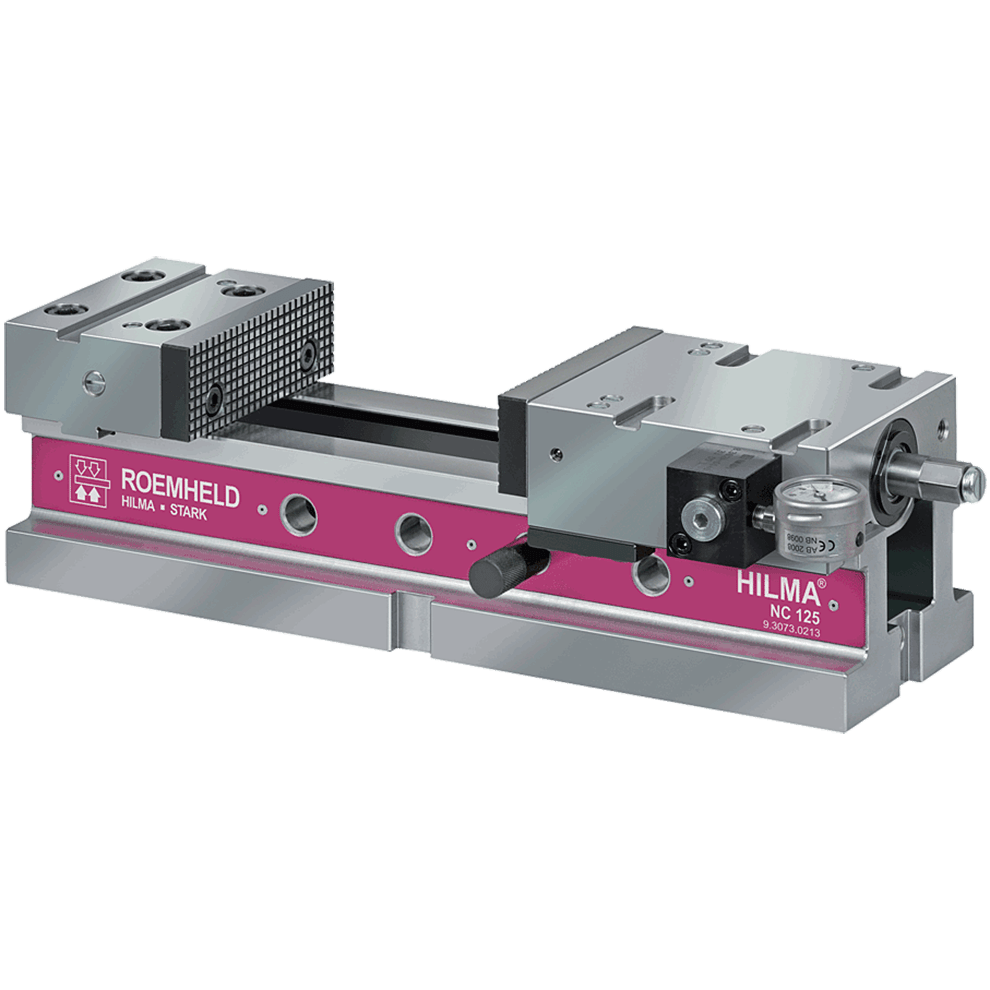

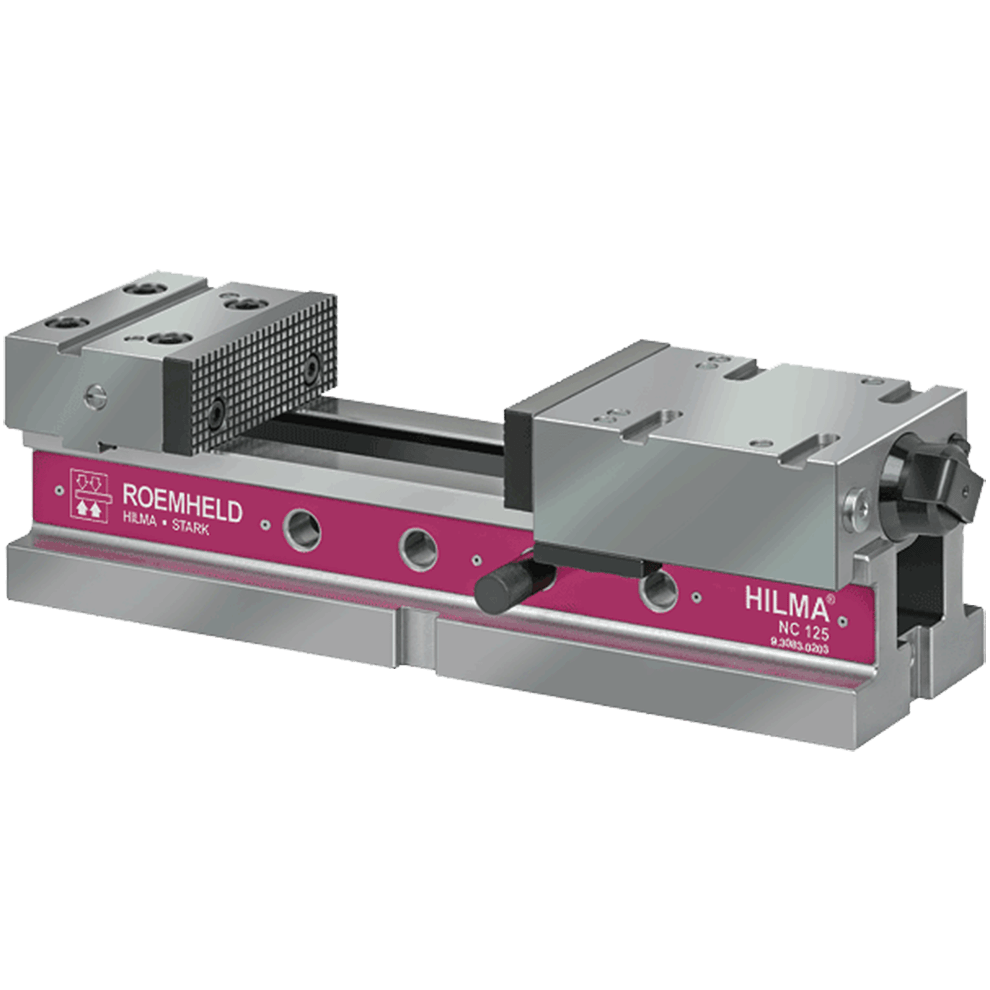

ROEMHELD NC Vises are uniquely robust German-made products. Machined from a solid billet of Tool Steel before induction hardening, few other vises provide a similar precision and repeatability. They are available in two activation styles; Hydraulically Operated and Hydra-Mechanical. While the Hydraulically operated versions are relatively standard the Hydra-Mechanical versions are unique in the market.

To Activate the Hydra-Mechanical NC Vise a hand crank is used. The hand crank turns a mechanical lead screw until the vise jaw contacts the workpiece. The operator must then advance the crank past a detent. Once this havehas been completed the turn of the hand crank compresses a Hydraulic fluid reservoir advancing the jaw and applying clamping force. This has several distinct advantages including low operator effort for clamping forces over 10,000lbs – higher than traditional vises. The use of hydraulics also allows for the addition of an accessory gage. This gage can provide visual feedback for the operator of the actual clamping force, preventing under or over clamping of workpieces. Learn more here.