Jigs and fixtures are indispensable tools in modern manufacturing, playing a crucial role in ensuring precision, consistency, and efficiency in production processes. These specialized devices are designed to securely hold, guide, and support workpieces, enabling machining and assembly. From reducing errors and production time to improving product quality, the applications of jigs and fixtures span a wide range of industries and manufacturing techniques. Carr Lane Mfg. produces industry-leading jigs and fixtures. For over 70 years, we’ve provided jig and fixture tooling components to many industries around the world, all proudly made in the United States at our production facilities in Austin, TX and St. Louis, MO.

In this article, the experts at Carr Lane Mfg. explore the key functions and benefits of jigs and fixtures, their various applications in manufacturing, and why they are vital for achieving high standards of performance and reliability. Whether you’re optimizing a production line or seeking ways to enhance your manufacturing processes, understanding the applications of jigs and fixtures can unlock new levels of efficiency and accuracy in your operations.

Learn more about the advantages of jigs and fixtures.

What are Jigs & Fixtures?

Jigs and fixtures assist with producing identical and interchangeable components in manufacturing facilities. In high-speed, mass production facilities, the ability to maintain consistency and quality across large volumes of products is essential. By improving precision and efficiency, jigs and fixtures play a key role in optimizing your manufacturing processes and ensuring superior product quality.

Jigs: Guiding the Tools

A jig is a device that helps with consistency, by guiding the tool to the exact position required for machining or assembly. Acting as a template or guide, the jig ensures the tool moves along the correct path, eliminating human error and improving accuracy. While in production, a jig controls and directs the cutting tool to a precise location on the workpiece, ensuring uniformity in every part produced. This precision is especially valuable in operations where even the smallest deviation can compromise the functionality or quality of the final product.

Fixtures: Holding the Workpiece

While the jig is guiding the tool, the fixture serves as a workholding device that securely holds and locates the work- piece being machined or assembled. A fixture keeps the workpiece stable and properly positioned, ensuring it doesn’t move or shift during the process. This stability is vital for achieving precision, especially when machining complex components or performing repetitive operations. Fixtures can be customized to accommodate specific shapes or sizes of workpieces, making them versatile tools for various manufacturing applications.

Jig & Fixture Applications: Internal Machining

Jigs and fixtures are essential tools in internal machining applications, where precision and consistency are paramount. These tools are designed to streamline the process of machining cylindrical and irregular holes, ensuring accurate, repeatable results across production runs. By providing secure workholding and tool guidance, jigs and fixtures enhance efficiency while minimizing errors, making them a critical asset for manufacturers in various industries.

Cylindrical and Irregular Hole

Internal machining applications often involve the creation of cylindrical or irregular holes in workpieces, tasks that demand high levels of precision and repeatability. To meet these requirements, manufacturers rely on a range of jigs and fixtures specifically designed for cylindrical and irregular hole machining applications:

-

Drilling jigs are used to guide drill bits with precision, ensuring accurate hole placement and depth. These jigs are particularly effective in repetitive production processes, reducing setup times and eliminating variations caused by human error. Carr Lane Mfg. offers a variety of high-quality drill bushings to support jigs, including gun, chip-breaker, and air-feed bushings.

-

Boring jigs are specialized tools that assist in enlarging existing holes precisely. They provide stability and accuracy, enabling manufacturers to achieve tight tolerances and smooth finishes, even in complex machining operations.

-

Electrical discharge machining fixtures hold workpieces securely during EDM processes, which use electrical discharges to remove material. EDM fixtures are crucial for achieving the precise, intricate shapes required in many advanced manufacturing applications.

-

Punching fixtures are designed to position and secure workpieces during punching operations, ensuring consistent hole shapes and dimensions. They are particularly useful in sheet metal fabrication, where accuracy and efficiency are key.

-

Internal broaching fixtures are used to hold workpieces during internal broaching, a machining process that removes material using a toothed tool. By providing stable and precise positioning, internal broaching fixtures enable the creation of complex internal profiles, such as keyways or splines.

Each of these tools is tailored to specific internal machining tasks, helping manufacturers achieve the exacting standards required for their products. By integrating the appropriate jigs and fixtures into their operations, manufacturers can enhance precision, reduce waste, and improve overall productivity in internal machining applications.

Jig & Fixture Applications: External Machining

Jigs and fixtures are essential tools for external machining applications, where precision and efficiency are critical to produce high-quality parts.such as: These tools are specifically designed to stabilize workpieces and guide machining tools, enabling manufacturers to achieve consistent and accurate results across a variety of surface types. From flat surfaces to cylindrical and irregular geometries, jigs and fixtures enhance production efficiency and ensure reliable machining outcomes.

Flat -Surface Machining

Flat surface machining requires stability and precision to achieve smooth, even finishes. Fixtures designed for flat surface machining help hold the workpiece securely in place, ensuring accurate machining without movement or vibration. Common fixtures used in flat surface machining include: There are also other uses for fixtures in cylindrical-surface and irregular-surface machinery, which are listed below.

-

Milling fixtures are tailored for milling operations, providing stability and alignment for workpieces during cutting. They are ideal for producing flat surfaces or intricate patterns, ensuring precision and repeatability in high-production environments.

-

Planing fixtures are used in planing operations, holding the workpiece securely as the cutting tool moves across the surface. They help achieve uniform flatness and are commonly used in the production of large, flat components.

-

Shaping fixtures stabilize workpieces for shaping operations, ensuring consistent results when creating flat surfaces, grooves, or other features.

Cylindrical Surface Machining

Cylindrical surfaces demand precise and consistent shaping, particularly in applications where roundness and even dimensions are critical. Fixtures for cylindrical-surface machining ensure that workpieces are held securely and aligned properly, allowing for uniform machining. The most used fixtures include:

-

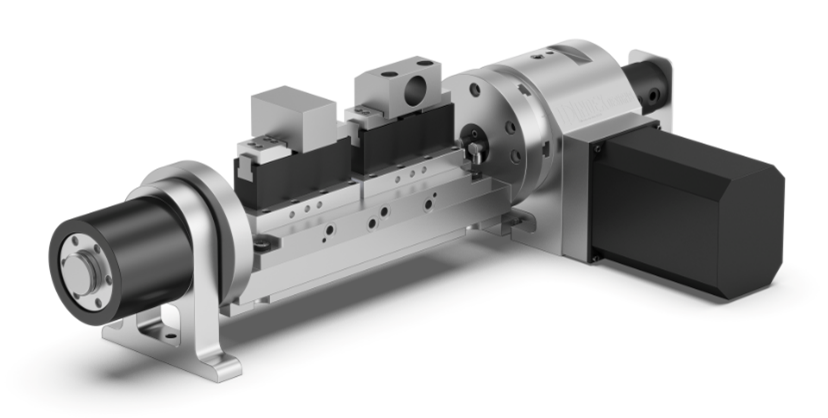

Lathe fixtures are designed for use in turning operations on lathes, holding cylindrical workpieces in place as they rotate. They enable accurate machining of shafts, rods, and other round components, ensuring consistent diameters and finishes. For example, the Martin Mfg. custom trunnion CNC machine uses the Carr Lock System and ROEMHELD compact clamps to achieve stability and accuracy.

-

Cylindrical grinding fixtures are used in grinding operations to achieve precise surface finishes and dimensional accuracy on cylindrical workpieces. They are particularly valuable in producing components like rollers, spindles, and pins.

Irregular Surface Machining

Working with irregularly shaped surfaces poses unique challenges due to their non-uniform geometries, especially in mass production facilities with high demands. Fixtures designed for irregular surface machining help stabilize these workpieces, improving production efficiency and accuracy. Common fixtures designed for irregular-surface applications include:

-

Band-sawing fixtures are used to secure irregular shaped workpieces during sawing operations, ensuring clean, accurate cuts while minimizing material waste. They are especially useful for cutting complex contours and shapes.

-

External broaching fixtures hold workpieces securely during broaching operations, enabling the creation of precise profiles on irregular shapes. These fixtures are essential for producing parts with unique external features like gear teeth or splines.

Non-Machining Applications of Jigs & Fixtures

Jigs and fixtures aren’t just essential for machining operations—they also play a critical role in non-machining applications. These versatile tools provide stability, precision, and efficiency across a range of manufacturing tasks, from assembly and inspection to finishing processes. By ensuring accurate alignment and secure workpiece support, jigs and fixtures help streamline operations and maintain high-quality production standards.

Assembly

In assembly operations, fixtures offer valuable support to the workpiece, allowing the operator to easily complete their job. By providing stability and proper positioning, these fixtures improve efficiency and reduce errors in assembly processes. Common fixtures used in assembly include:

-

Welding fixtures stabilize components during welding, ensuring proper alignment and consistent weld quality. They are essential for producing strong, reliable joints in a variety of industries.

-

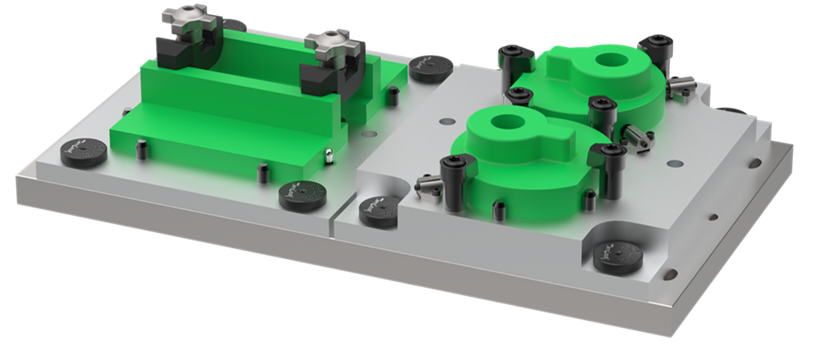

Mechanical assembly fixtures are designed for processes like riveting, stapling, stitching, and pinning, simplifying repetitive tasks by holding components securely in place. They allow operators to perform mechanical-assembly operations quickly and accurately. For example, the image below shows a Carr Lock System Tombstone being used for fast and easy part changes in hydraulic fixturing.

-

Soldering fixtures provide a steady platform for components during soldering operations, ensuring precise connections in applications like electronics manufacturing.

Inspection

Inspection is a crucial step in ensuring the quality, reliability, and safety of each component. Fixtures used in the inspection process hold workpieces securely, allowing for accurate and thorough evaluations. These fixtures include

-

Mechanical inspection fixtures are used to position parts during mechanical testing, ensuring that measurements and evaluations are consistent and reliable. As shown in the image below, this can include captive hand knobs, L pins, clamp straps, and cables.

-

Optical inspection fixtures are designed for use with optical instruments, providing stability and alignment for components being inspected for visual defects or dimensional accuracy.

-

Electronic inspection fixtures assist in testing electronic components, ensuring precise connections and functionality during the inspection process.

Finishing

At the end of your manufacturing process, finishes provide the extra appeal to your product, enhancing its appearance, functionality, and durability. Fixtures designed for finishing applications provide the support needed to achieve consistent results across multiple parts. In the image below, the manufacturer is using Clip Buddy, along with toggle clamps and the Hoist Eye 360®, to check durability and polish the car component. Examples of finishing processes include:

-

Painting fixtures secure workpieces during painting operations, ensuring even coverage and preventing smudges or inconsistencies.

-

Plating fixtures are used in plating processes, holding components securely to ensure uniform coating and adherence of plating materials.

-

Polishing fixtures stabilize parts during polishing, enabling smooth, even finishes that enhance the visual appeal of the product.

-

Lapping fixtures help achieve high-precision flat surfaces or finishes during the lapping process, which involves fine abrasive materials.

-

Honing fixtures are used to refine the surface finish or dimensional accuracy of holes, improving the functionality and performance of components.

Miscellaneous Applications

Jigs and fixtures also support a variety of other manufacturing processes that fall outside traditional machining, assembly, inspection, or finishing operations. These include:

-

Layout Templates: Fixtures can be used as templates to guide layout markings for machining or assembly tasks, ensuring accuracy and repeatability.

-

Testing Fixtures: Testing fixtures stabilize workpieces during performance or durability testing, allowing for consistent and reliable results. In the image below, captive jig pins, L pins with cables, bullet nose dowel pins, and slotted locator bushings are used to test the strength and durability of aerospace components.

-

Heat-Treating Fixtures: These specialized fixtures hold components securely during processes like annealing or tempering, ensuring uniform heating and cooling to achieve desired material properties.

Find High-Quality Jigs & Fixturesfor Any Application at Carr Lane Mfg.

At Carr Lane Manufacturing, we’re proud to offer high-quality, American-made jig and fixture solutions that support precision and efficiency in a variety of manufacturing applications. Our extensive range of products is designed to meet the diverse needs of manufacturers across industries, providing reliable tools that enhance productivity, reduce downtime, and ensure consistent results. Whether you’re working on machining, assembly, inspection, or finishing applications, our jigs and fixtures are engineered for durability and performance.

With decades of experience and a reputation for innovation, Carr Lane Mfg. is committed to delivering solutions that empower manufacturers to achieve their goals with confidence. Whether you’re looking for standard components or customized solutions, we have everything you need to optimize your manufacturing processes. Explore our full selection of jigs and fixtures or reach out to our experts to find the perfect solution for your operation today.